_SPORTS PITCH DRAINAGE

_Drainage systems can be installed on existing sports fields with very

little disruption or damage to the playing surface. A waterlogged pitch

can be out of action for as long as 3 months during the winter -

mid-season for football and rugby. To solve this problem drainage

systems can be installed out of season to prevent disruption to team

fixtures. These drainage systems fall into two main categories:

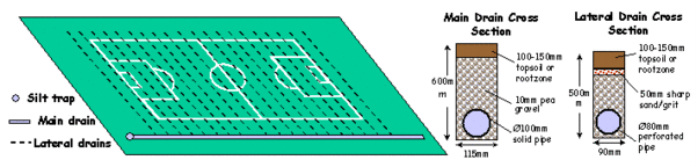

- primary lateral systems to existing pitches

- secondary systems: sand banding and gravel banding

SECONDARY DRAINAGE

If the lateral drains alone are not sufficient to remove all surface water a secondary surface drainage system can be installed over the primary lateral system. There are two types commonly used: sand grooving and sand banding. We can install both types, but the latter, more expensive method of sand banding is recommended as it has greater drainage potential and lasts longer.

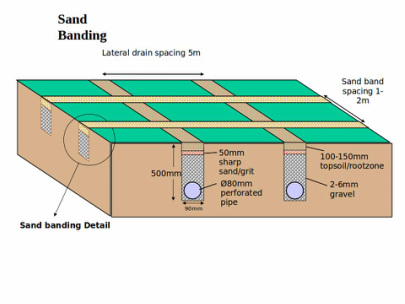

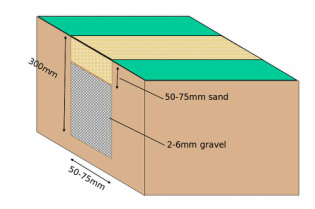

Sand Banding

Slits or trenches, 50-75mm wide and 200-300mm deep, are inserted with the Shelton Super Trencher at 1-2m spacings. They are back filled with 2/6mm gravel and topped with 50-75mm of rootzone. They are designed to tie-in with existing lateral drains. Heavy top dressings of suitable sand are essential for the successful construction and management of sand banded pitches.

Our Blec Sandmaster putting grooves in.

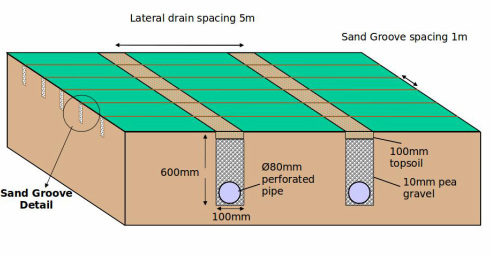

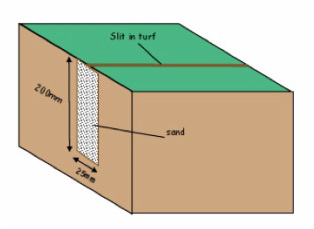

Sand Grooving

Sand grooving is a method of rapid surface drainage. Sand grooves are installed at 250mm centres 200mm deep 10-15mm wide and filled to the surface with medium fine sand. Advantages of this system is there is very little growing in time required and pitches can be played on quickly.

Sand Dressing

Sand dressing simply applies up to 10mm of sand to an existing surface. This greatly improves the surface structure of the soil and increases the surface drainage.

Sand dressings are commonly applied to ensure that pitches do not become capped with the drains sealed over. Each dressing uses between 60-100 tonnes of sand, depending on the size of pitch.

Sand dressings are commonly applied to ensure that pitches do not become capped with the drains sealed over. Each dressing uses between 60-100 tonnes of sand, depending on the size of pitch.